Buying a new and used car is fraught with the need to find answers to a whole scattering of questions. To begin with, future car owners look at a suitable body type, manufacturer, and a specific model. Further, the nuances of the configuration and technical characteristics are taken into account.

It is a mistake to believe that only the engine is the key issue when choosing technical characteristics. In fact, the role of the gearbox is no less significant. You won’t surprise anyone with classical mechanics. Everyone knows that this is the simplest, cheapest, but also the most reliable transmission option. Previously, machines were treated very carefully due to their low level of reliability and high maintenance costs. But modern automatic transmissions have reached a completely new level of quality and durability. New types of boxes have appeared. Therefore, more and more motorists are interested in what is better: a variator or an automatic machine.

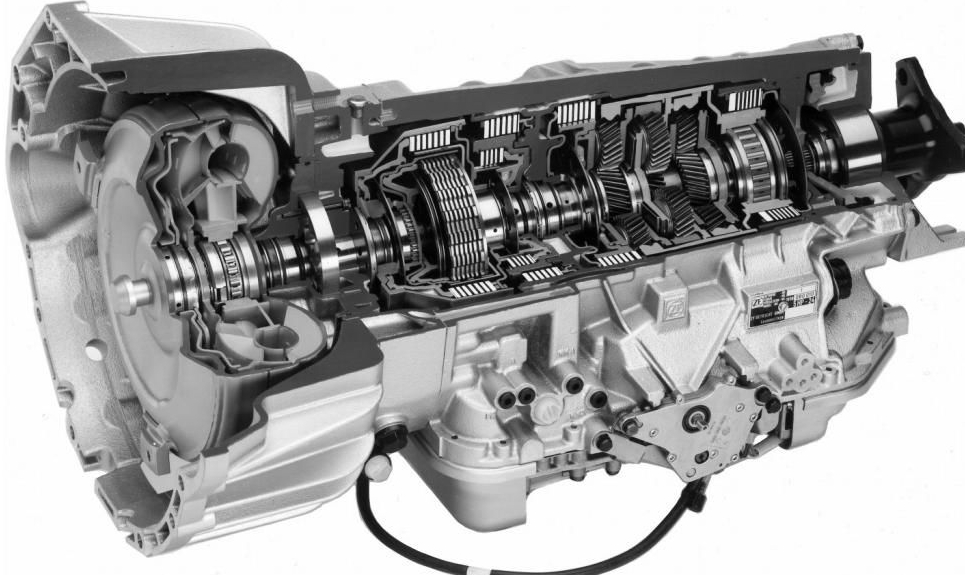

Features of automatic transmission

When a variator or an automatic transmission is offered to choose from, objectively, without studying the issue in more detail, it is impossible to say which is better. To do this, you need to understand the essence of each type of transmission, study its features, design and principle of operation. It should be noted right away that the comparison will be between a classic automatic and a variator, which is actually a kind of automatic transmission. The machine is controlled using a special selector or shift knob. It is usually installed in the area of the central tunnel, but on some cars, mainly American manufacturers, it is located on the steering column. The selector provides the opportunity for the driver by moving the switch to select one of the available operating modes, including Drive, Parking and R, which is required for reversing. As automatic transmissions improved, the number of modes increased significantly. More and more often, on modern cars, even with not the most expensive models, machines provide for the presence of special driving modes necessary for winter movement, sports driving or maximum fuel economy. A classic automatic machine structurally consists of a planetary gearbox, a torque converter and a special control system. Automatic transmissions can be used on cars, trucks, buses and even on special wheeled vehicles. The converter includes a turbine and an impeller, between which the reactor is located. The pump wheel is directly connected to the crankshaft of the motor, and the turbine wheel is connected to the gearbox shaft. Depending on the mode in which the reactor is operating, it can be blocked by an overrunning clutch or be in a state of free rotation. The torque from the engine to the gearbox is transmitted due to the fluid flow, which is the transmission oil. It is fed by the impeller blades to the turbine-type impeller blades. There are minimal gaps between the wheels of the torque converter, and the blades themselves are specially shaped to create a continuous circle for the circulation of the working fluid. This ensures that there is a rigid connection between the motor and the gearbox, which is necessary for smooth transmission of tractive effort. The torque converter is capable of converting rotational speed and delivering torque within a strictly limited range. Because of this, a planetary multistage gearbox is connected to it, which also allows you to drive a car with an automatic transmission in reverse. Gears are shifted by creating high oil pressure. Friction clutches play an important role in this process. The pressure arising between them is distributed by the control system, which consists of a control unit and solenoid valves. The conditional disadvantage of the automatic transmission is that it is quite expensive and also consumes more fuel. But these are rather controversial disadvantages, since modern machines have reached a new level of efficiency. Many of them are at least not inferior to the classic manual transmissions, and sometimes even surpass in terms of fuel economy. The study of the features that the automatic transmission has does not make it possible to say that it is better if the variator is a competitor. First you need to consider the characteristics of the variator transmission itself.

Variable speed drive

The essence and meaning of the variator box, which is referred to as CVT, is no different from any other transmission. The essence of the device is to convert the torque that comes from the power unit to the wheels. But a distinctive feature of the variator is that the torque is transmitted continuously. A certain regulation range is provided here. It is this characteristic that significantly differs a classic automatic machine from a variator. As for the abbreviation CVT, it stands for Continuosly Variable Transmission. This name can be translated as transmission or gearbox with continuously changing torque. You have already roughly understood how variators differ from automatic machines and what is the main difference between them. But this is objectively not enough to give preference to any of the two options. Also, the difference between the variator and the classic machine lies in its design features. There are 3 main types of CVT, which are: chain; V-belt; toroidal. If we talk about passenger automobile transport, then here the most popular and widespread were the V-belt varieties of the variator gearbox. The V-belt variator includes a V-belt. It is located directly between the two sliding pulleys. While the vehicle is in motion, these pulleys are constantly compressed and unclenched, thereby providing changes in the gear ratio. The main task of the variator is to create a smooth and stepless change in torque. Such systems are actively used in passenger cars, as part of snowmobiles, two-wheeled vehicles, etc. The next type of variator box is chain CVT. Power transmission here is carried out due to the beveled ends of the axle of the chain links. And the pulling force itself is transmitted using a special chain. Such variators are not widely used, although they are sometimes found. Toroidal variators replaced the pulleys with tapered discs. And instead of a belt, special rollers were used here. They are characterized by the fact that they can transmit a sufficiently large torque. But in order to create such details for the layout of the variator box, it is imperative to use high-strength steel grades. This negatively affects the cost, which has led many automakers to abandon the idea of installing similar CVTs on their vehicles. Given the obvious differences in design and principle of operation, it is easy to understand what is the difference between the two types of gearboxes under consideration. At the same time, the automatic transmission and the variator are a worthy solution, each of which has its own strengths and weaknesses. If we talk about the advantages characteristic of CVT or continuously variable transmissions, then the main advantage here is the provision of a continuous change in torque. There is no delay moment, which is typical for automatic transmissions, where there is a transition from one gear to another. The stepless and continuous variator provides other benefits in the form of more efficient fuel consumption and improved dynamic performance of the engine. Cars with CVT consume less fuel and provide better acceleration dynamics. At the same time, the variator also has some obvious disadvantages. To begin with, CVTs are not designed for use on powerful engines. Installation on a car with increased power does not allow using the potential of the box. It will quickly deteriorate and wear out. CVT can be considered a relatively new development in the field of automotive transmissions. Therefore, engineers have not yet figured out how to increase the resistance of the variator to high loads, towing and active driving at high speeds. In such conditions, the variator belt wears out quickly, and the entire transmission breaks down. Repairing and restoring a CVT is quite an expensive pleasure, often exceeding the cost of repairing a classic machine.

Comparison of two gearboxes

To determine the favorite of this pair, an objective comparative characteristic should be carried out. It will also make it clear how you can visually distinguish the variator from the machine. Initially, the main focus of the comparison should be on performance. Consumers are rightly interested in the question of which is more reliable: an automatic machine or a variator. Also, many people want to know who will be the favorite in such an indicator as economy. Let’s start with the efficiency indicator. Here, several parameters should be taken into account at the same time so that the assessment is as objective and fair as possible. Transmission lubricating oil. Each gearbox, including an automatic and a variator, must use a lubricant. It is periodically required to change the oil in the box. Although the manual for some machines with automatic transmissions indicates that oil is filled for the entire service life and cannot be replaced. This is a rather controversial issue, largely depending on the specific operating conditions, the state of the box and the service life of the machine itself. If we compare the variator and the classic automatic transmission, the transmission lubricant in the CVT box needs to be changed more often. At the same time, the fluid for variator gearboxes itself is more expensive than ATF grease intended for an automatic machine. Fuel consumption indicators. Having studied the pros and cons that characterize the automatic machine and the variator, you probably noticed that among the advantages of the CVT is high fuel efficiency. Therefore, on this point, the preponderance is on the side of the variator. Even the most modern automatic transmissions cannot demonstrate the same efficiency as cars with a CVT. Repair and service. There are no eternal and immortal gearboxes. It is a fact. Each transmission at some point requires repair work, maintenance and preventive maintenance. From the point of view of operating costs, the variator turned out to be much cheaper. The thing is that the structure of the CVT includes complex, expensive and sensitive mechanisms. They fail more often, and therefore require more money from the car owner. One amendment needs to be made regarding the last point. The cost of the CVT box itself is lower when compared with a competitor in the face of an automatic transmission. But it’s cheaper to service a classic machine. The operating costs for repairs and maintenance are largely dependent on how the car owner will treat the car and monitor the condition of the transmission. Even with a variator, in the case of correct operation, no overloads and aggressive driving, the CVT will last a very long time and will not require large financial investments for a long service life. But if we talk purely about maintainability and maintenance cost, the advantage will still be on the side of the classic automatic transmission. Now you should compare the candidates for their reliability. In many ways, the reliability of the transmission is manifested in its ability to maintain its performance in harsh operating conditions. These include: towing; high speed; off-road driving; aggressive driving style. There is an obvious advantage on the side of the classic machine. It is ordinary automatic transmissions that are much better at coping with such difficult operating conditions. Of course, they are inferior to mechanics, but in comparison with a variator, they turn out to be preferable. It is important to understand that the weak point of the variator is its belt. Its current reliability is low enough for tough and challenging CVT driving conditions. In such presented conditions, it does not withstand for a long time, there is a breakage and breakdown. CVTs are suitable for those who prefer to drive smoothly, accurately, without sudden acceleration or braking, except in an emergency. Having understood the difference between variators and automatic machines, certain conclusions can be drawn. Moreover, each motorist perceives the information presented in his own way.

Additionally, many are interested in how to find out if there is an automatic machine on the car, or a variator. There are several ways to identify the type of transmission used. The visually presented boxes are really similar to each other. Visual method. The first step is to start from external features. But this is one of the most unobvious ways to determine the use of an automatic machine or variator on a car. Some CVTs have a corresponding marking on the selector, therefore it is recommended to carefully study the gear lever. On classic machines, not only the designations P, R, N and D are used, but also type 2, 3 and L markings are often found. For variators, only mode L is used. Although much depends on the specific box, and this method of determination will not always be correct. Technical documentation. If you do not know how to distinguish the CVT box from the automatic machine, purely by the lever, then the easiest way is to look into the documents for the car. Open the section with the gearbox. If you have a machine gun, then you will see the corresponding AT marking. CVT designation is always used for variators. Real operating conditions. Simply put, a test drive. On CVT gearboxes, the gear shifting process is not felt. Therefore, the box is called continuously variable. In the case of a machine gun, you can feel or notice from the tachometer needle how the revolutions change with a certain delay at the moment of transition from one gear to another. Although new CVTs began to be equipped with a special mode, which is designed to simulate gear changes. Hill test. Another way to quickly determine which box is at your disposal. To do this, you need to drive onto a section of the road with a slight rise, and stop the car completely there. Then release the brake pedal and do not step on the gas. The selector remains in the Drive position (D or Drive). If the car gradually moves uphill, you definitely have an automatic machine. In the case of a variator, the car will first roll back a little and then stop. But such a test is relevant for those variator boxes where there is no anti-rollback system. In the most difficult situation, when there are no documents, no designations are provided on the selector, and you yourself cannot accurately determine the box by testing, go to the service station or to the nearest car service, where a qualified technician will answer all your questions.

Summarizing

Summing up, you can try to answer the question about which is better: a variator or an automatic machine. If we start purely from the indicators of popularity and prevalence, then the machine will be the undisputed favorite in this confrontation. But we must not forget that the history of CVT boxes is actually just beginning. This is a relatively new type of transmission, which has yet to undergo numerous modifications, upgrades and improvements. It is difficult to say what the variator will be literally in 3-5 years. Its potential is huge, and therefore at some point the CVT can really surpass the classic machine gun. Which transmission is best depends on the specific situation. It is worth choosing a variator with measured and calm city driving without unnecessary loads. And the automatic machine is suitable for those who buy a car with high power and require towing trailers. If we talk about efficiency, then there is an advantage on the side of the variator box. In terms of reliability, the machine wins so far.